We would have purchased a medicine from a nearby pharmacy many time, but do you how would this medicine would have arrived at that particular pharmacy/medical store. It covers a lot of stages from raw material of salt formation to manufacturing a medicine at manufacturing plant, to storing at central warehouse, then it go through various stakeholder such as C&FA, Super stockists, distributors, sub-distributors/stockists and then to retail shops (hospital pharmacies or local chemist shops) and then finally to you. This process in real life is more complex than what it looks in this written form. This whole process of getting the medicine manufactured to getting it to the retail shops is the supply chain.

The Pharmaceutical supply chain is the means through which prescription medicines are manufactured and delivered to patients. But, the supply chain in Pharmaceutical Industry is complex and is very different in developed and developing countries. SCM costs are higher in India than in other areas of the world, amounting to 13% of India’s GDP.

Pharma supply chain, like other supply chains ,struggle with common issues like supply management, bottlenecks in logistics, costs and delivery customer satisfaction. The pharmaceutical supply chain faces its own set of challenges, including supply chain visibility, drug counterfeiting, cold-chain shipping, and raising prescription drug prices, which can significantly increase out-of-pocket costs for patients.

In B2B marketplace, the retailers, hospital pharmacies are not able to see what medicines do their distributors have. Basically there is no visibility about the no. of SKUs with distributors, Qty. of each SKU available, knowledge about Scheme on a particular medicine etc. Supply chain visibility across your enterprise is the first step towards improving customer loyalty, brand reputation, and the ability to foresee issues, but it requires more discipline and data than you think. Very few logistics professionals have complete supply chain visibility, mostly due to a dearth of quality data as well as their reliance on manual tracking processes.

The other issue in Pharma industry is Bullwhip effect(in other words, inventory or demand mismanagement) because of which forecasting of demand cannot be done properly. This results in higher cost impact evry stakeholder negatively on performances and more.

The other issue is Reverse Logistics. The product returns percentage in the Indian pharmaceutical industry varies from 1.5% to 15% of annual sales across the companies in the domestic market. The annual estimated value of these returned medicines translates to around 5 billion Indian rupees. The main reasons for the return of the products from downstream players to the companies are the expiry of the medicines, followed by issues of quality with drug composition/packaging, and the non-moving nature of the products.

Now, what can be the solutions for these problems.

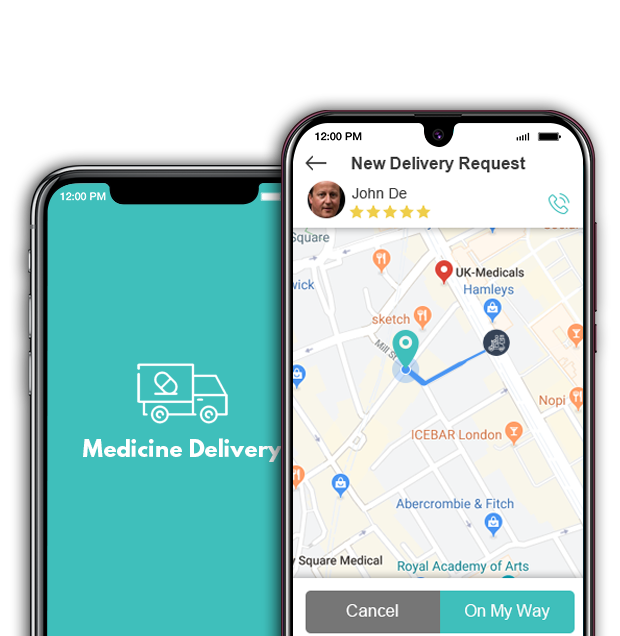

So for the first problem i.e Visibility issue technology can play an important role. A proper visibility of what medicines are available at what price, quantity wise etc through tech. can make the visibility and transparency better.

The problem of Bullwhip effect can be solved by predictive analysis, and change in the type of models to supply the medicines(with moving towards more closer to JIT models). The simplest way to control the bullwhip effect caused by forward buying and diversions is to reduce both the frequency and the level of wholesale price discounting.

The other problem of reverse logistics or returns can be solved by technology itself. The main part of reverse logistics is because of expired or near expiry medicines. So proper visibility and inadvance updation details can help in making the reverse logistics better. The proper information about a customer(retailers, in house pharmacies) medicine bbuying behaviour and with technology to keep watch of the fast moving medicine can help in making the returns item to the lowest.

So overall solution for the above problems is technology and data usage to make the supply chain better in coming days.

A digitized supply chain is an automated, optimized set of processes that ties your supply chain together end-to-end, and uses data and predictive analytics to improve its performance.

You are probably balancing multiple, sometimes even conflicting business objectives — delaying the fulfillment of an inventory request to avoid shipping sub-products. If you had an enterprise monitoring solution that gave you visibility and predictive analytics across your supply chain, you could be better equipped to deal with this conflict by shipping these goods from an alternative location which might have the stock.

Security, logistics, and transportation all benefit from a digitized supply chain in a global enterprise.

The benefits accrue across your departments/divisions with immediate and transparent ROI that ripples through the entire enterprise and on to the customer’s experience.

Just as your supply chain is the beating heart of your enterprise, data is the lifeblood of your digitized supply chain. For big pharma, it’s not just one piece of data, but the collective intelligence that is important to pharma enterprises, collective intelligence that includes, inventory levels, asset utilization levels, lead time in manufacturing, time/cost benefits, and of course, brand reputation. A digitized IoT enabled supply chain can also provide you with real-time dashboards, improve transportation efficiencies, collate information that helps better decision making, as well as handle a plethora of other tasks that you wouldn’t be able to quite as easily through email and an ERP.

So, we can take bottom up approach to solve this issue like giving visibility to retailers, hospital pharmacies to give proper visibility about medicines their distributors have and managing the return with expiry details available with the help of data and technology. This approach can at least, solve the two stages of pharmaceutical supply chain which further can help in organizing this sector itself.